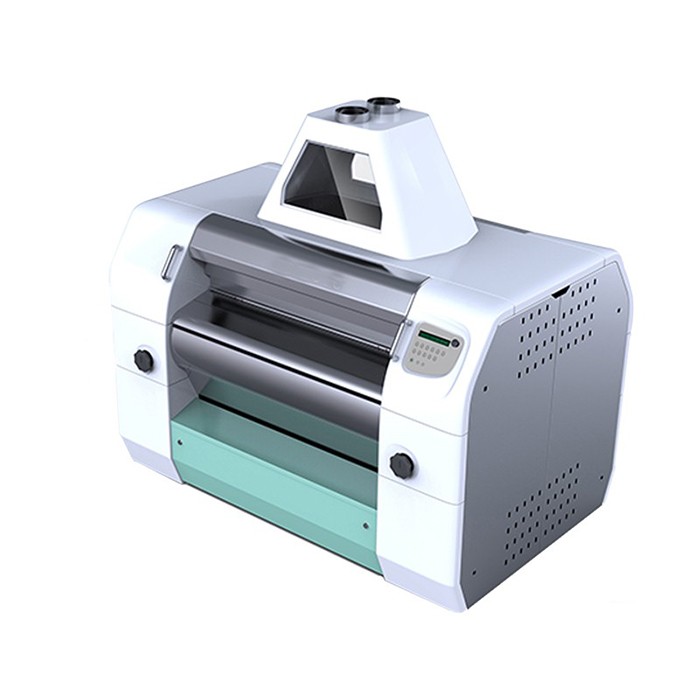

Roller Mill Maintenance Flour Roller Repair Machine

- AGS

- JIANGSU

- 30 DAYS

- 10000 SETS

The quality of grinding roller and wire drawing in flour mill industry is an important embodiment of the operation of grinding machine. It has more prominent influence on output, distribution of work in process, flow balance and quality, output rate and power consumption of final products

Flour Roller Repair Machine

Function parameters of CNC direct wire drawing machine: firstly, high-quality frequency converter is equipped in CNC direct wire drawing machine to realize PLC system control and humanized interface display. Secondly, an external pneumatic tension wheel sensor is used in the machine, which is stable in adjustment and convenient in operation. Can is 560 spray can, hardness 60 degrees, no jumper, no pressure line. The hopper part adopts all-round adjustable hopper, with uniform outgoing line and no slub wire. Secondly, in the production of the drum part of the CNC straight wire drawing machine, especially the cast steel spray tungsten carbide, or hardfacing wear-resistant alloy material, hardness HRC > 60, good wear resistance. The cooling mode adopts narrow slot cooling and annular air cooling. Taper design is reasonable: to ensure that the line is not broken or disordered. In practical operation, the transmission system is stable and reliable, the transmission is stable, and the coincidence degree is high, the noise is small; it can also be driven by a class I strong narrow V-belt + standard hard tooth surface gearbox.