Bulk Material Handling Flour Bulk Loading System

- AGS

- JIANGSU

- 30 DAYS

- 1000 SETS

Bulk material conveying process system is a new bulk material handling process for metallurgy raw materials, chemical material yard, bulk material wharf, building aggregate, fuel material yard and other fields.

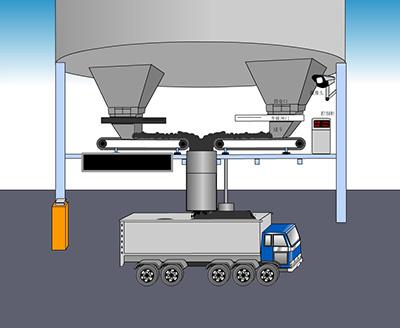

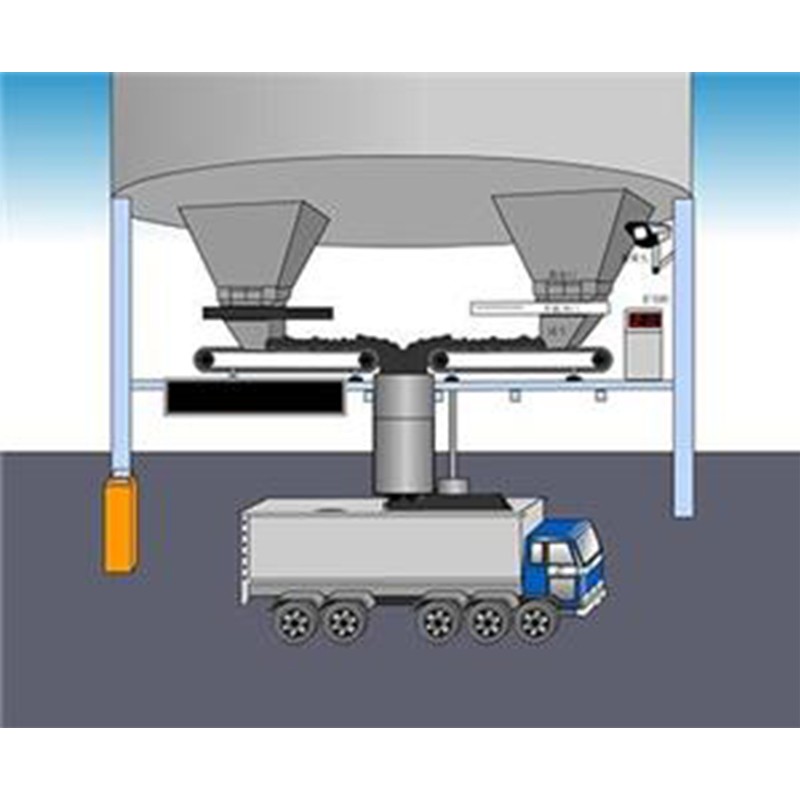

Flour Bulk Loading System

A bulk flour system stores, sifts, conveys, andautomatically weighs out exactly the amount of flourneeded each time. The system is dust-free and lowmaintenance and will give many years of trouble-freeservice.The basic bulk flour system includes: Truck unloading station, Storage silos, Pressure or vacuum conveying, Sifter,Scale hoppers for weighing out batches, Control system to operate the system, Dust collection systemMore sophisticated systems may include: Railcar unloading, Intermediate storage bins – called use bins or day bins, Multiple conveying systems, Separate systems for whole wheat or other specialty flours, Computer batching systems for multiple recipes and MIS usesRelated systems are (see separate brochures): Bulk sugar systems, Minor ingredient systems, Powdered sugar systems, Liquid ingredient systems, Batching control systems.

Handling flour with a bulk system offers many advantages:

1. Significant cost savings over bagged flour.

2. Higher production than manual systems.

3. Better batch quality, accuracy and control.

4. Space and labor savings.

5. Eliminates risk of injury from handling heavy bags.

6. Eliminates dust, bag breakage and empty bag cleanup.